Water treatment plant

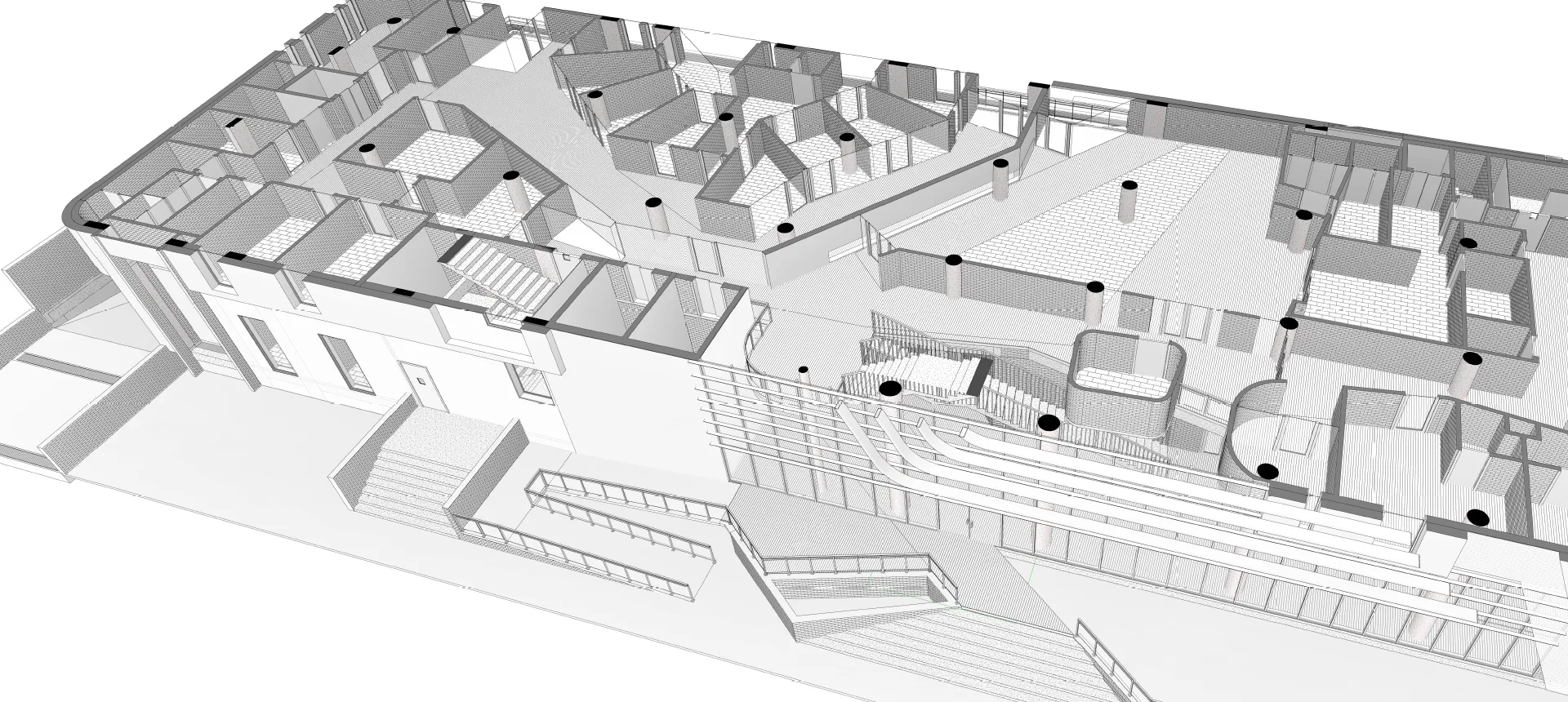

Schematic Level BIM Modeling for Budgetary Estimation and Board Approval of a Water Treatment Plant

Project Overview

Comprehensive BIM modeling for water treatment facilities, focusing on process flow, equipment layout, and structural integration.

Ensures accurate coordination of civil, mechanical, and piping systems. Designed for operational efficiency, compliance, and future scalability.

| Client Profile | An Industrial Contractor |

| Location | UAE |

| Industry | Industrial |

| Inputs | CAD drawings |

| Deliverable | Schematic level BIM model and BOQ for budget approval |

| Software Used | Revit |

| Project Size | 1 Millon Sqft |

The project commenced with the receipt of typical 2D CAD General Arrangement (GA) drawings. These drawings provided foundational information regarding the proposed layout and preliminary dimensions of the water treatment plant. While traditional methods would involve extensive manual interpretation and quantity take-offs from these 2D inputs, the adoption of BIM enabled a more efficient and accurate approach.

Schematic Level BIM Model Development:

Upon receiving the CAD GA drawings, a schematic level BIM model was developed. This initial model focused on representing the primary elements of the water treatment plant at a conceptual or “scheme” level of detail (LOD 100-200). Key components integrated into this model included:

- Major Building Structures: Outlines of treatment basins, pump houses, control rooms, and chemical storage facilities.

- Primary Equipment: Placeholder representations of large capital equipment such as clarifiers, filters, pumps, and disinfection units, based on their anticipated size and location from the GA drawings.

- Main Piping Runs: Conceptual routing of major process piping, indicating general paths and connection points.

- Structural Elements: Basic representation of columns, beams, and foundations for the main structures.

The development of this schematic BIM model involved transforming the 2D CAD data into a preliminary 3D environment. This allowed for early spatial coordination and identification of potential conflicts that would be difficult to discern from 2D drawings alone.

Budgetary Estimation from BIM Model:

A core advantage of the schematic BIM model was its direct utility for budgetary estimation. Unlike traditional methods that rely on manual quantity take-offs, the BIM model allowed for the extraction of preliminary quantities for various project components. Specifically, cost estimations were derived from the following extracted data:

- Capital Equipment: The placeholder models for major equipment provided a basis for initial equipment sizing and, consequently, approximate procurement costs. While detailed specifications were not available at this stage, the modeled dimensions and typical capacities allowed for reasonable budgetary pricing.

- Piping: The schematic routing of main pipes enabled the estimation of linear footage for various pipe sizes and materials. This facilitated a preliminary assessment of piping material and installation costs.

- Structural Work: The basic structural elements modeled (columns, beams, foundations) allowed for volume calculations of concrete, steel, and formwork, providing a preliminary estimate for structural construction costs.

The quantities extracted from the BIM model were then cross-referenced with historical cost data and industry benchmarks to develop a comprehensive budgetary estimate. This approach significantly reduced the time and potential for error associated with manual quantity surveying.

Board Approval & Visualization:

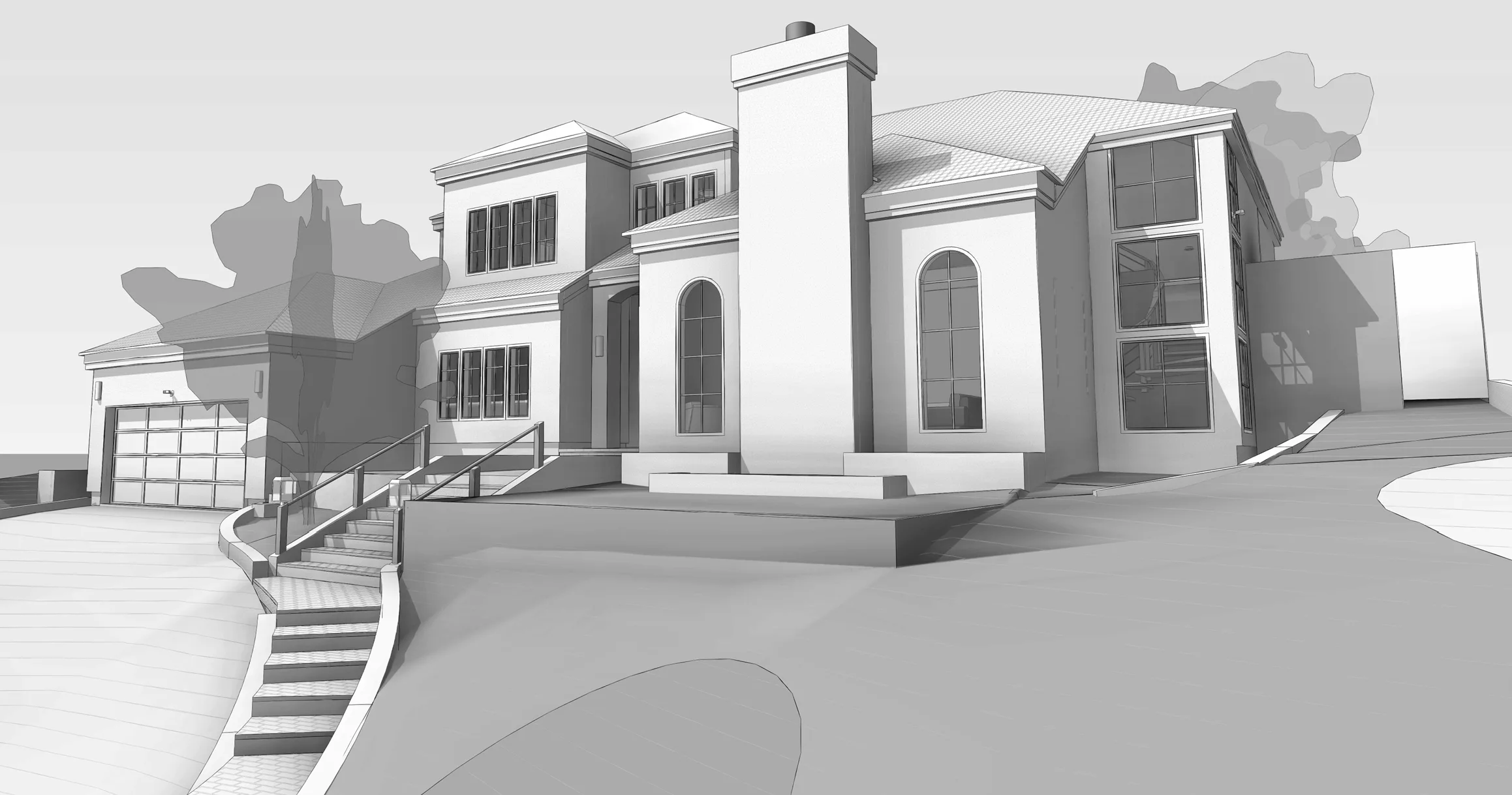

The schematic BIM model proved invaluable for presenting the project to the board for budgetary approval. Beyond numerical estimations, the 3D visual representation offered by the BIM model allowed board members to:

- Visualize the Proposed Plant: Gain a clear understanding of the plant’s layout, scale, and spatial relationships in a way that 2D drawings cannot achieve.

- Understand Scope: Easily comprehend the overall scope of the project, including the relative sizes and positions of major components.

- Facilitate Informed Decision-Making: The enhanced visualization and clear presentation of cost drivers, directly linked to the modeled elements, enabled more confident and informed decisions regarding project funding and direction.

- Identify Early Risks: Discussions around the 3D model could uncover potential spatial or constructability issues at a very early stage, allowing for proactive mitigation strategies.

Ready to Elevate Your Construction Projects?

At Next Synergy, we believe that the future of real estate and construction is digital, collaborative, and datadriven. Whether you’re planning a new project or looking to optimize your existing workflows,

we have the expertise and technology to make it happen.

View More Projects

Explore more of our cutting-edge projects, where innovation meets real-world impact

- All

- Commercial

- Community

- Data Center

- Education

- Healthcare

- Hospitality

- Industrial

- Infrastructure

- Interior Fitouts

- Residential

- All

- Commercial

- Community

- Data Center

- Education

- Healthcare

- Hospitality

- Industrial

- Infrastructure

- Interior Fitouts

- Residential