Façade - ACP

Façade BIM Modelling and Documentation for ACP Systems

Project Overview

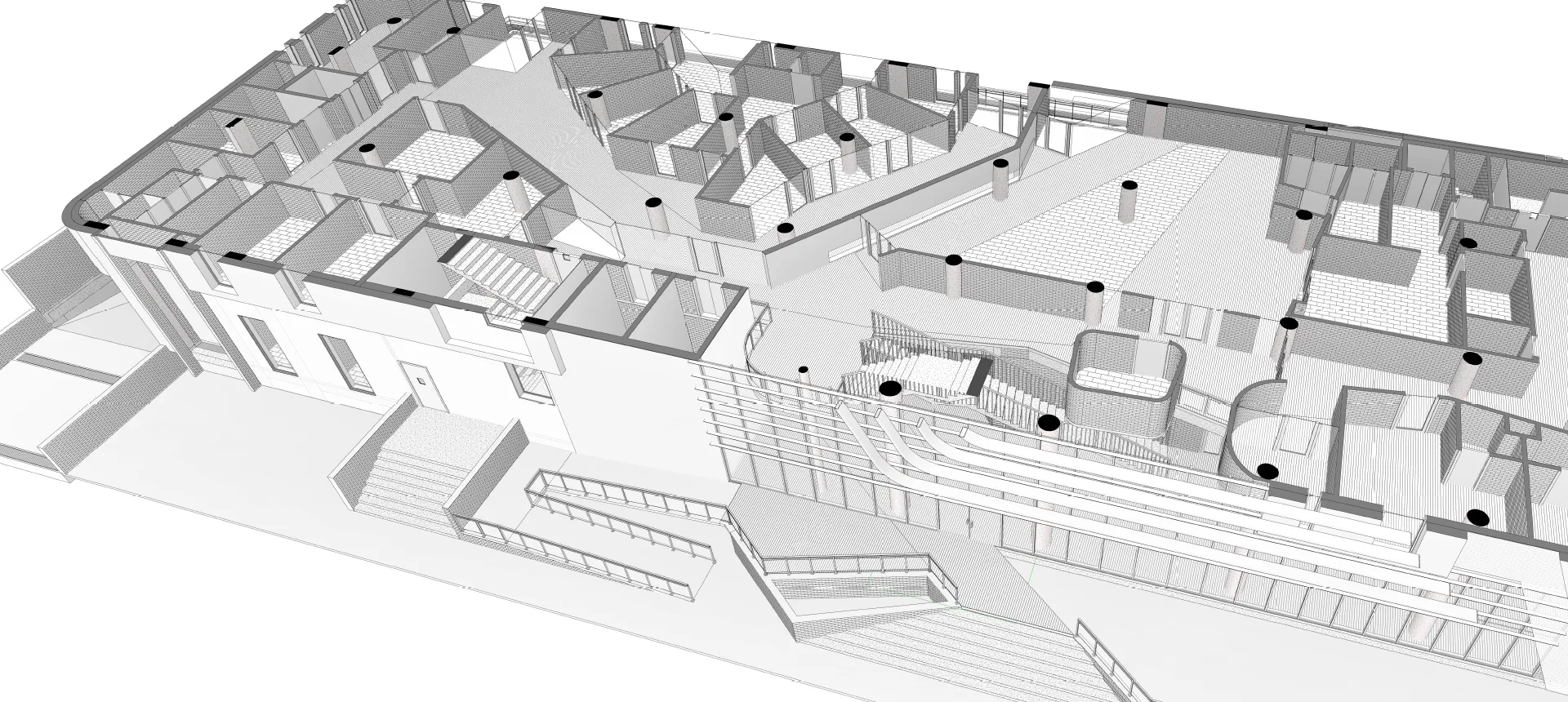

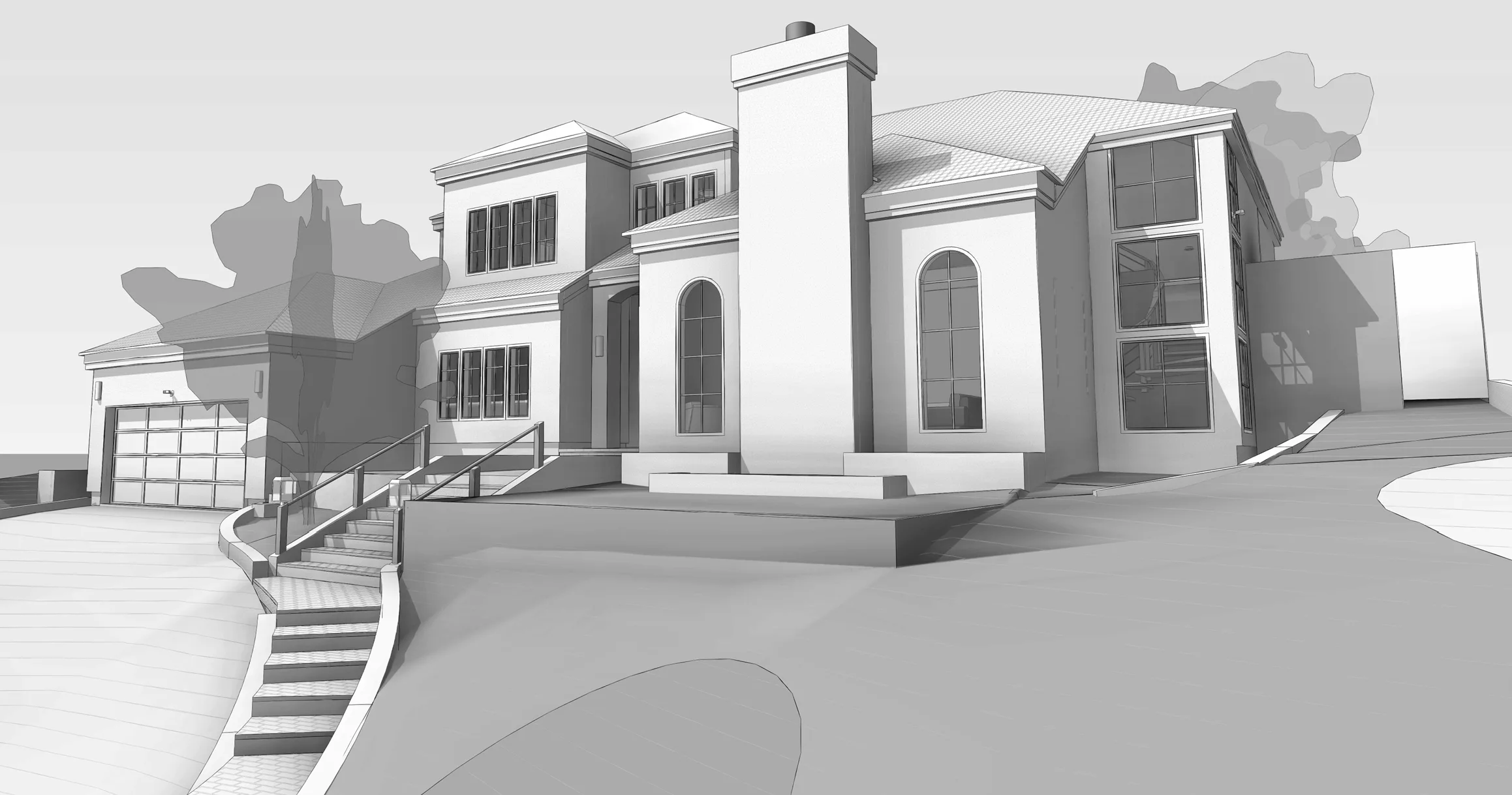

Detailed BIM modeling of Aluminum Composite Panel (ACP) façade systems tailored for modern architectural designs. Focuses on panel layouts, joint detailing, and sub structure coordination.

Ensures aesthetic precision, thermal performance, and structural compatibility.

| Client Profile | Façade Consultant based at Chicago, USA |

| Location | Charlotte, USA |

| Industry | Commerical |

| Inputs | Architectural BIM Model, Façade CAD drawings, GA drawing |

| Deliverable | Clash free Façade BIM model, BOQ and BOM , Febrication Drawings |

| Software Used | Revit, Dynamo, AutoCAD |

| Project Size | 40,000 Sqft |

Appointed by a façade consultancy firm to deliver a comprehensive BIM model and construction documentation package for an ACP (Aluminium Composite Panel) façade system, the objective was to develop a clash-free, fabrication-ready façade model that aligns with the architectural intent and aids in accurate procurement and execution.

Project Inputs:

We received the following inputs as the starting point:

- The architectural BIM model (Revit format)

- CAD drawings detailing the ACP façade panel layouts and sections

- General Arrangement (GA) drawings indicating overall envelope geometry and reference levels

Scope of Work & Execution:

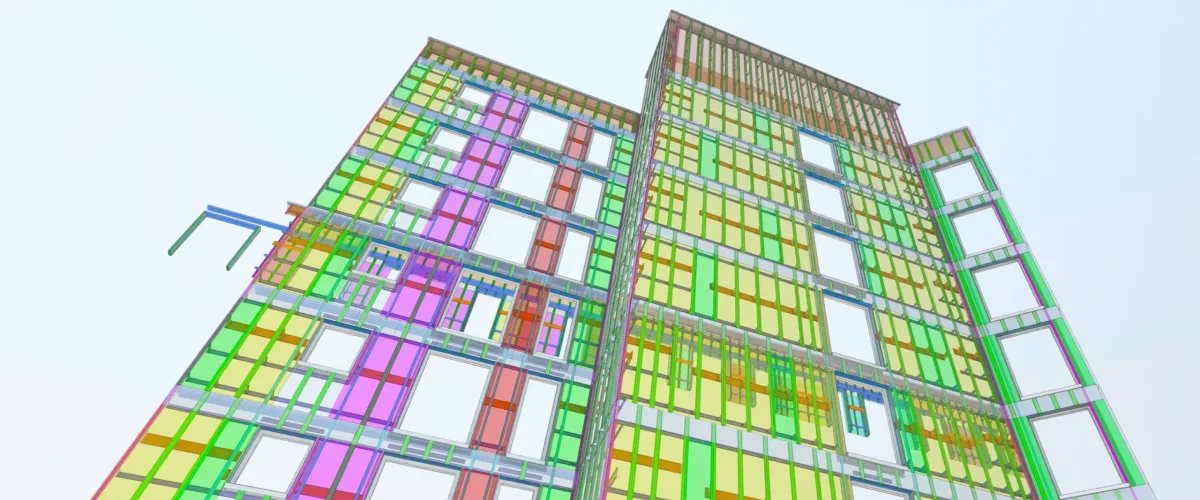

Our scope involved creating a precise LOD 300 BIM model of the façade elements with accurate geometry, material build-up, and embedment details. One of the core requirements was to coordinate the façade system with the base architectural model and structural elements to eliminate potential clashes during installation. Using Dynamo scripting, we automated repetitive panel placement, reducing manual effort and ensuring consistency across panel patterns and sub-framing systems.

Each panel was accurately tagged with geographical location data, ensuring that every component could be traced to its physical position on-site for both logistics and assembly tracking.

Deliverables:

- Clash-free coordinated BIM façade model

- Detailed shop drawings with panel IDs and sub-structure layouts

- Bill of Materials (BOM) and Bill of Quantities (BOQ) generated directly from the model

- Schedules and tagging for each unique ACP element, aiding in precise ordering and fabrication

The integrated model and data-rich outputs significantly improved material management for the consultant, reduced wastage, and streamlined fabrication and installation workflows. The project demonstrated how parametric automation and BIM coordination could bring clarity and control to complex façade systems.

Ready to Elevate Your Construction Projects?

At Next Synergy, we believe that the future of real estate and construction is digital, collaborative, and datadriven. Whether you’re planning a new project or looking to optimize your existing workflows,

we have the expertise and technology to make it happen.

View More Projects

Explore more of our cutting-edge projects, where innovation meets real-world impact

- All

- Commercial

- Community

- Data Center

- Education

- Healthcare

- Hospitality

- Industrial

- Infrastructure

- Interior Fitouts

- Residential

- All

- Commercial

- Community

- Data Center

- Education

- Healthcare

- Hospitality

- Industrial

- Infrastructure

- Interior Fitouts

- Residential