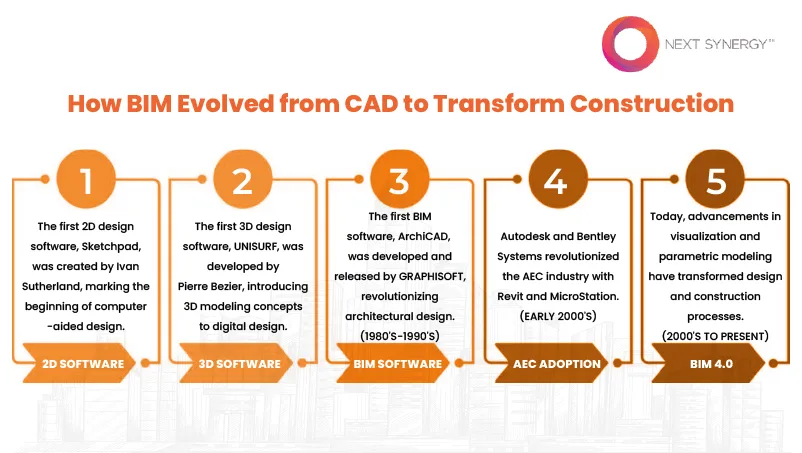

The 1960’s were dominated by 2D tools such as Sketchpad. It gave architects their first taste of digital design. The late 1960s saw the introduction of 3D software, such as UNISURF. It was a huge leap which added a new dimension to the design.

The 1980s brought ArchiCAD (the first genuine BIM software). From there, adoption only grew.

During the early 2000s, platforms such as Revit and MicroStation emerged. They became standard in the AEC industry. And today we have BIM 4.0, which dominates with cloud collaboration, parametric modelling, and advanced visualization.

All these evolution stages have set the stage for the next big leap, which is in Artificial Intelligence (AI). With AI, the BIM, which primarily served as a digital model, is now becoming a dynamic system. You can track progress with computer vision, spot deviations faster, and even reduce the reporting cycles. For instance, the AI-driven “optioneering” compresses schedules and recovers lost weeks. Automated takeoff reduces estimator workload by 60–80%.

In fact, the market too reflects this momentum. By 2030, BIM is expected to surpass $15–23 billion, with AI driving much of that growth.

That’s the future of BIM, which doesn’t just rely on the models but adds intelligence, automation, and integration.

Let’s find out more about it.

Where BIM Stands Today

BIM is now embedded in construction workflows across the world. Adoption levels are high, with regional differences that indicate the pace at which the momentum builds.

Take a look at how BIM is adopted across the world, with Europe leading the adoption, as 89% of projects use BIM, followed by North America, which follows at 72%. Even in Asia, Australia sits close at 75%. Asia is at 63%, and South America is at 49%.

These numbers prove BIM is already a global standard, not an experiment.

But still, many firms struggle with adopting because of the challenges in areas like —

- Data silos: Project information may remain locked in separate systems. This makes it hard to maintain a single source of truth unless you leverage design documentation services.

- Interoperability: Different software platforms may not always sync smoothly, which slows down the collaboration and adds extra steps

Training gaps: Skilled BIM users are limited, and rolling out training across entire teams takes time and resources

Emerging Trends Shaping BIM’s Future

BIM’s next chapter shows itself through a few clear trends that we’ve discussed below.

AI & Automation

Generative design enables you to test and visualize optimal layouts in minutes, particularly with clash detection & coordination services. For example, you get the AI-driven clash detection that scans complex models. In one tunnel project in China, BIM combined with an AI-based “dynamic optimization framework” enabled real-time schedule shifts, smarter resource use, and sharper risk control.

Digital Twins

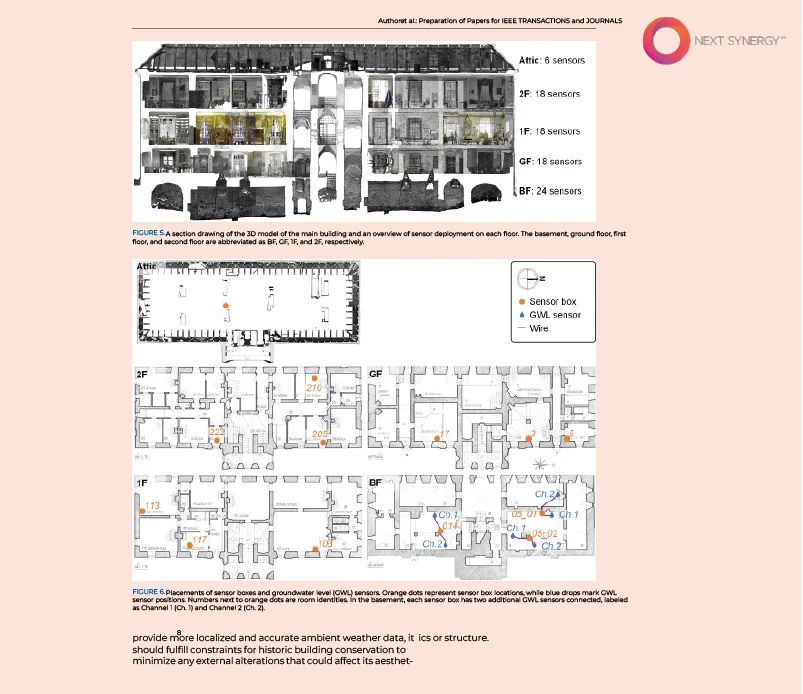

There are sensors that feed live data into BIM-based twins. It is useful in monitoring the building’s health, detecting anomalies, and predicting maintenance needs.

At Löfstad Castle in Sweden, teams used 84 sensors to build a digital twin that tracks indoor climate and drives HVAC decisions.

Cloud & Collaboration

Moving models, data, and workflows into the cloud busts silos across offices, contractors, and stakeholders. Tools like Revizto let everyone review, annotate, and sync from anywhere.

For example, in Mexico, a construction team adopted cloud collaboration using BIM Collaborate Pro and cut sync delays by 50% vs. their old hybrid setup.

AR/VR & Immersive Tech

Teams can use VR to mitigate design conflicts and enhance stakeholder buy-in. A study found that combining BIM and VR reduces design conflicts by 37% and enhances spatial understanding by 48%.

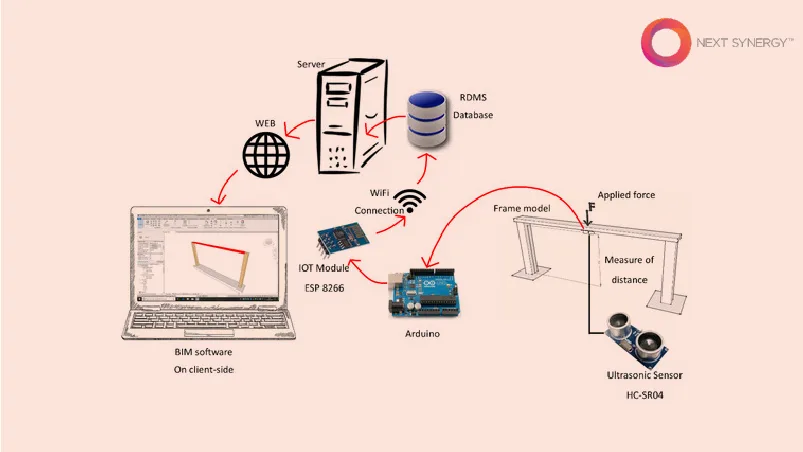

IoT & Smart Buildings

Sensors feed live data into the building ecosystem to monitor temperature, humidity, structural strain, and occupancy. All these are then fed into BIM.

In one bridge-beam experiment, researchers integrated IoT sensors with a BIM model to detect deflection in real-time (as seen in the image).

An ultrasonic sensor was applied to a structural element modelled in 3D through BIM software running on a remote, network-connected computer.

Robotics & Prefabrication

Letting BIM drive the parametric design can enable robots to build façades or structural elements with high precision.

A study on façade design shows how the researchers used BIM and robotic fabrication to optimize solar exposure while minimizing material waste.

Sustainability Through Carbon Tracking

BIM makes carbon visible across the entire lifecycle, right from the way a business would source materials to how buildings operate and eventually get reused. A case study in China showed its impact clearly: when applied to prefabricated buildings, BIM workflows cut carbon emissions by 70.6% during reuse cycles.

BIM also tracks the carbon from material sourcing through to operation and reuse. There’s one case study in China which highlights how BIM can be utilized in prefabricated buildings, resulting in a 70.6% reduction in carbon emissions in subsequent reuse cycles.

BIM Across the Lifecycle

Lifecycle means every stage—design, construction, operations, and even eventual renewal. BIM across the lifecycle means BIM modelling services helping AEC businesses leverage live data and adapt. AI adds a layer of predictiveness and does not just let BIM be descriptive.

Design

AI in BIM reshapes design. There’s a transformation of static drawings into adaptive systems that test, learn, and optimize in real-time.

Generative workflows

There’s no need to manually test a handful of layouts. Instead, set rules and performance goals such as airflow, light, or cost efficiency by leveraging construction cost estimation services. AI can run across hundreds of design options in minutes to highlight tradeoffs and show you which ones best meet your targets.

Parametric modeling

Parametric tools already update geometry when you tweak dimensions. AI in power would mean those updates carry intelligence for decisions like shifting a wall, and the model recalculates energy use, cost impacts, and structural stability instantly.

Construction

On-site, AI shifts BIM from a planning tool to an execution engine, linking robotics, drones, and AR to build with speed, precision, and fewer errors.

Robotics

Robotic arms and autonomous machinery take BIM data as instructions. On-site, they can handle repetitive tasks such as bricklaying, rebar placement, or façade installation with millimetre precision. Studies on BIM-guided robotics show reduced errors, faster execution, and less reliance on scarce skilled labour.

Drones

Drones in BIM can help capture high-resolution imagery, mapping progress against the BIM model, and identifying discrepancies that can be fed back to project managers. With AI processing, drones can spot unsafe zones, unfinished work, or deviations long before manual checks would catch them.

AR-assisted site management

Workers wearing AR glasses can see the BIM model overlaid on the physical site. This means piping, ducts, or wiring appear exactly where they should be. And, it can lead to fewer conflicts, faster inspections, and less rework.

Operations

In operations, AI makes BIM a living model which can monitor conditions, predict failures, and continuously drive efficiency over the asset’s lifetime.

Digital twins

A twin links sensors with the BIM model to reflect a building’s real condition minute by minute. Facility managers can monitor energy usage, occupancy, and structural performance in real-time. It’s not a record—it’s a mirror that updates continuously.

Predictive maintenance

Instead of waiting for breakdowns, AI reads patterns in vibration, temperature, or airflow data. It predicts failures before they happen, schedules interventions automatically, and extends the useful life of assets. Studies show predictive BIM workflows can cut maintenance costs by double-digit percentages.

Energy optimization

AI provides live simulations of how a building consumes and produces energy. For HVAC, it can predict occupancy patterns and adjust heating or cooling before demand spikes. Also, it’s easy to optimize the lighting schedules using daylight sensors to reduce electricity use without compromising comfort.

What’s Next in BIM After 2035: Future Ideas

Ten years from now, the role of BIM will certainly not be limited to being a passive coordination platform. In fact, it’d evolve into something larger, a sort of operating system for the built world.

You’d imagine that by 2035, BIM will act in the following areas to reshape the foundation for A&E businesses.

Construction Sites Can Go Fully Autonomous

Automation is already happening in areas such as drones and robotics. But by 2035, we could have entire sites with minimal human intervention as the model becomes a command hub for machines.

By 2035, there’ll be:

- Robot-driven assembly where they handle repetitive, precision tasks like rebar tying or façade installation, guided directly by BIM.

- Dynamic scheduling based on AI which can continuously update work sequences as conditions change

- Drone oversight that scans progress, feeds deviations back into BIM, and triggers adjustments instantly

Smart Contracts Will be Based on Blockchain

The self-executing, tamper-proof agreements will become smart contracts backed by blockchain. With regards to BIM, every clause will be tied directly to data in the model. That means there won’t be ambiguity or delays because of fewer intermediaries.

In the next decade, this transforms into —

- Automated milestones where contractors receive payment the moment BIM data confirms work is complete and verified on-site

- Supply chain trust with every delivery, from steel beams to HVAC systems, gets tracked on blockchain, eliminating disputes.

- Regulatory transparency for auditors to access immutable BIM-linked records, simplifying compliance

BIM Can Build Smart Cities

By 2035, BIM may expand beyond buildings to manage entire urban systems. It becomes the data layer connecting infrastructure, utilities, and mobility.

From 2035 onwards, smart cities will have BIM in the following applications:

- City-scale digital twins for every street, utility, and building that’ll feed a live model for planning and crisis response

- Energy balancing, where grids pull building data from BIM twins to optimize loads

- Predictive services for water, waste, and transport systems that could be adjusted based on predictive demand analytics

AI-Driven Compliance Checking

Instead of relying on manual reviews, AI embedded in BIM cross-checks every design choice against local and international codes. This creates real-time compliance.

In the next decade, we can see AI for BIM in functions such as—

- Instant validation through architectural modeling services, where AI can flag code violations on the spot

- Adaptive libraries based on AI systems that maintain live databases of building codes across multiple regions.

- Regulator access for governments to plug directly into BIM outputs and approve projects faster

Practical Roadmap for Stakeholders

For different stakeholders in the AEC chain, there’s something new and unique as BIM evolves with AI.

Here’s what to expect for different entities.

For Owners

Owners need to bring AI into their vision now. Because BIM is not just limited to project delivery. In fact, it consists of lifecycle performance and ROI. So, they’ll have to demand BIM deliverables which can remain useful beyond construction and push teams to deliver models that track cost, maintenance, and energy.

For Contractors

Contractors must close the skills gap and embrace automation. AI-driven BIM does make functioning on sites safer and more efficient, but that’s only true if teams can be trained and systems remain integrated.

For Architects/Engineers

The design process is shifting really fast. Especially in Generative and parametric workflows. These divisions provide more options, faster iterations, and better performance outcomes.

Conclusion

We have learned that BIM is now an intelligent framework that guides design, construction, and operations with real-time insight. Certainly, it has gone far beyond the digital drawings. Instead, it’s a shift that suggests that the data is no longer passive; it drives decisions, reduces risk, and extends asset value across the lifecycle.

Owners, contractors, designers, and other stakeholders who lean into that shift will be able to derive a specific value that others might miss.

If you’re serious about staying ahead, start with a partner, a BIM Company that helps leverage the next-gen technology. At NxtSyg, we bring accuracy, speed, and lifecycle value to your next project.

Ready to take the next step?

Experience the power of BIM-driven precision and innovation for your next residential build.

Book Your Free BIM Consultation Today