BIM, or Building Information Modeling, is now driving the Architecture, Engineering, and Construction (AEC) industry’s push for precision and accountability. In practice, it’s a shared 3D model layered with rich project data of materials, quantities, timelines, and costs.

AEC work spans architectural BIM services, structural engineering, MEP Engineering, and BIM for infrastructure, all the way to BIM facility management after handover. Those in the industry use it as a single-model workflow because BIM is proven to cut design errors by up to 40%.

The AEC sector spans BIM for everything from concept design to on-site construction. It also includes long-term facility management from architectural BIM services, Structural BIM services, and MEP BIM services. Combine it with the rising demands of urban development, tight regulatory standards, and clients expecting faster turnarounds. The BIM modeling services ensure unlocking those needs without budget slips as a solution to drive measurable results.

Read on for a more in-depth understanding of BIM.

What is BIM?

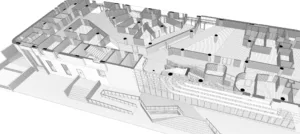

Building Information Modeling, or BIM, represents a method in the AEC industries to create and manage a digital version of a physical asset, such as buildings, bridges, etc.

There’s a 3D drawing involved in this process, but it represents a model that holds information on geometry, materials, costs, schedules, and performance data.

Typically, a BIM engineering company is engaged to create and manage the BIM workflow. Their task involves digital representations of physical and functional characteristics of buildings.

But BIM is not just CAD software or another digital way to represent a construction. It’s a way of connecting drawings, schedules, material specifications, and cost data so they move together instead of in silos.

For instance, if you change the wall thickness by a few inches, then the quantities, timelines, and even downstream trade drawings will update instantly.

History and Evolution of BIM

BIM evolved from a hand-drawn blueprint. Every change meant redoing entire sheets by hand. The shift to computer-aided design (CAD) sped up revisions, reduced drafting errors, and made design work more precise.

From there, 3D modeling brought another leap forward, allowing teams to see depth, spot potential clashes, and understand spatial relationships before any work began on site.

Here’s a quick look at the history and evolution of BIM:

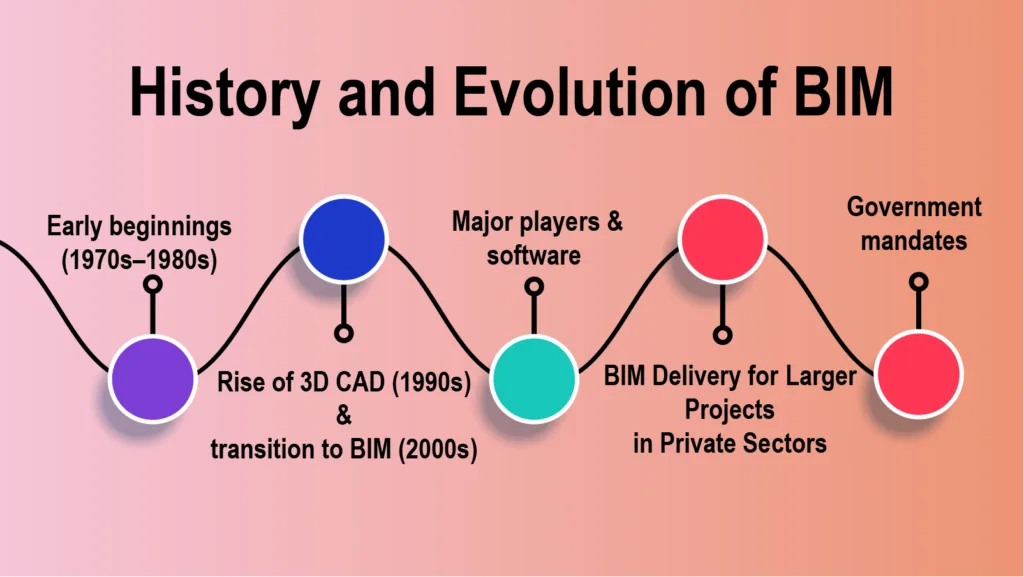

A. Early beginnings (1970s–1980s)

You’d track the roots of BIM back to systems like the Building Description System (BDS), which aimed to store detailed building information in digital form.

- Drawings were mostly 2D, often reworked manually.

- Coordination relied heavily on printed plans and on-site meetings.

- Data storage was basic, limiting reuse across projects.

B. Rise of 3D CAD (1990s) and transition to BIM (2000s)

This is when 3D CAD was introduced. And then there was a leap to BIM, which added

embedded data and collaborative workflows to it.

- Design changes are updated across views automatically.

- Clash detection reduced costly rework.

- The early 2000s saw shared models replace isolated files.

C. Major players and software

Some tools support BIM by blending geometry, specifications, and timelines in one live model. Some of the primary tools used in the BIM modeling services are:

- Autodesk Revit

- Graphisoft Archicad

- Bentley Systems MicroStation

- Trimble Tekla Structures

D. BIM Delivery for Larger Projects in Private Sectors

The private sector developments grew in scale and complexity. And this moved BIM adoption beyond public mandates and government-driven projects. Builders adopted BIM for large commercial, residential, and industrial buildings to coordinate multiple contractors, suppliers, and design consultants.

- Centralised models help manage lage amounts of design and construction data

- Real-time coordination reduce delays on multi-phase, multi-stakeholder projects

- BIM-supported scheduling and cost tracking

E. Government mandates

Mandates pushed BIM from an option to a requirement in many regions that set standards for model structure, data exchange, and collaboration.

- UK BIM Level 2 standardized digital collaboration on public projects.

- ISO 19650 was introduced as an international standard for managing information across the project lifecycle.

- Singapore BIM Roadmap laid out phased adoption across industry sectors.

BIM Dimensions From 3D to 7D and Beyond

BIM dimensions are layers of extra intelligence added to the base 3D model. The starting point is geometry and spatial layout, such as walls, beams, doors, and mechanical systems placed precisely where they belong.

Each new dimension layers on a fresh set of project data, turning the model into something you can actually work with. It becomes a tool in you can interrogate, test, and trust to guide design, construction, and day-to-day operations.

3D BIM | Geometry and spatial accuracy

3D BIM is also called the foundation of BIM since it captures the exact size, shape, and position of every building element. Teams can go through the design in detail, measure precisely, and detect conflicts before construction begins.

4D BIM | Time and sequencing

Here, the model is linked to a construction schedule, so each activity is mapped to specific dates. It will help teams coordinate work phases and avoid delays.

5D BIM | Cost intelligence

Costs are tied directly to the model’s elements, meaning budgets update instantly when designs, materials, or quantities change.

6D BIM | Sustainability insight

Energy performance, carbon footprint, and lifecycle impact can be assessed during design, helping meet environmental goals early.

7D BIM | Facility management

The model stores operational details like maintenance schedules, manuals, and warranty data to support long-term building upkeep.

8D+ | Specialized layers

This is a layer suggestive of an additional dimension. It includes safety planning, prefabrication logistics, and other construction data tailored to the project’s needs.

Software Tools Used in BIM

Most BIM outsourcing services have teams that rely on software to handle the flow of information that keeps design, engineering, and construction aligned.

Autodesk Revit

Many BIM projects would start with the use of Revit. It’s where architectural modeling services collaborate with structural teams and MEP engineers to build the core model. For instance, a wall design will contain thickness, material, fire rating, and cost code.

Navisworks

This tool is a powerful one, heavily used during coordination phases, as contractors and project managers can work in sync to pull models from multiple disciplines into one environment.

Bentley Systems

Bentley Systems is a well-known name in large-scale infrastructure, as it offers tools like MicroStation and OpenBuildings. These can handle rail, highway, and utility projects where data from civil, structural, and geospatial sources must merge cleanly.

Graphisoft Archicad

Design-led architectural modeling services may choose Archicad for its strong modeling capabilities with built-in IFC support. It becomes easier to exchange detailed models with engineers and contractors without getting locked into a single vendor ecosystem.

Trimble Tekla Structures

This one is a go-to for structural steel and reinforced concrete since Tekla’s models are build-ready down to bolt holes and rebar bends.

Who are the Stakeholders involved in a BIM Workflow?

Various stakeholders in the BIM workflow work as a network of contributors working inside one shared environment. Collectively, these stakeholders drive the model from concept to construction and into long-term operation.

A few of the common stakeholders are:

Architects

Those offering architectural modeling services or independent contractual architects can lead the design phase by setting the foundation. It’s where other disciplines are built with engagement in:

- Defining spatial layouts, aesthetics, and material specifications

- Integrating sustainability features early in design by leveraging BIM Integration services

- Providing coordinated drawings and model data for engineers

Structural Engineers

These personnel are responsible for ensuring the model’s design is physically realised while meeting safety and performance requirements.

Their role includes —

- Adding structural frameworks, load calculations, and reinforcement details

- Coordinating structural systems with architectural and MEP models

- Flagging and resolving conflicts that impact constructability

MEP Consultants

MEP teams can contribute to modeling and optimizing the building systems so they fit seamlessly within the architectural and structural design, with inputs in the following areas:

- Designing HVAC, electrical, and plumbing layouts with accurate routing.

- Running performance simulations for energy efficiency.

- Resolving clashes between systems and other building elements.

Contractors

In a BIM workflow or even in the case of BIM outsourcing, contractors translate the BIM model into an actionable construction plan by:

- Using 4D BIM for scheduling and site sequencing.

- Aligning procurement with model-based quantity take-offs.

- Planning logistics to reduce delays and waste.

BIM Coordinators / BIM Managers

BIM managers and coordinators have a responsibility to maintain data quality and keep the model aligned across disciplines with the following actions in the BIM workflow:

- Set and enforce modelling standards and protocols.

- Manage version control and the Common Data Environment.

- Facilitate coordination meetings to resolve design conflicts.

Owners and Facility Managers

The end users are owners and facility managers who use the final BIM model as a long-term asset management tool. They leverage it to:

- Specify asset data needs during design and construction.

- Use 7D BIM for maintenance scheduling and lifecycle planning.

- Support future renovations with accurate as-built data.

Steps To Implement BIM Workflow

The workflow of a BIM modelling service operates in a structured manner. It has a series of steps in a phased format, evolving into a process where data, geometry, and decisions move forward together.

Step #1. Conceptual Design & Schematic Design

This first stage translates project objectives into spatial ideas. Architects and planners explore form, massing, and orientation while assessing site conditions, zoning rules, and environmental constraints.

- Massing models define the shape, footprint, and building volume

- Preliminary site and environmental analysis guide early decisions

- Visualisations and diagrams help secure stakeholder approval

Step #2. Detailed Design

The model develops through Levels of Development, gaining precision with every pass. Architecture, structure, and MEP systems are modelled in parallel, embedding specifications, performance data, and materials.

- Parallel modelling across all design disciplines

- Detailed specifications and performance data are embedded into elements

- Clash resolution before documentation handoff

Step #3. Construction Documentation

At this stage, the coordinated model generates permit-ready drawings, schedules, and precise quantity take-offs.

- Permit-ready drawings generated automatically

- Accurate quantity take-offs tied to model data

- Built-in compliance checks reduce rework

Step #4. Simulation & Analysis

It’s here that the design is validated for clash detection, structural analysis, and MEP simulations to confirm buildability.

- Clash detection eliminates system conflicts

- Structural and MEP simulations confirm capacity

- Energy and lighting analysis improve building performance

Step #5. Construction Execution (4D/5D)

The BIM process enters the build phase, where BIM Integration services can align architecture, structure, and MEP systems to define time and cost in the model. 4D BIM maps construction sequencing, while 5D BIM updates budgets in real time, aligning procurement with actual progress.

- 4D sequencing for accurate project timelines

- 5D live cost tracking is tied to the model

- Procurement is linked directly to quantity take-offs

Step #6. Handover and Operations (6D/7D)

It’s a final stage that delivers a complete as-built model with asset data for facility teams that supports preventive maintenance, lifecycle planning, and future renovations.

- As-built updates reflect the constructed reality

- Asset data supports maintenance scheduling

- Accurate models guide future upgrades

Technical Advantages of BIM

BIM changes the way projects run. It is a working environment where design, engineering, and construction teams can actually stay aligned.

The gains are obvious once you’ve seen it in action.

Clash detection and risk reduction

Spotting a duct running through a beam in a model is far cheaper than discovering it halfway through a build. BIM catches those conflicts early, saving both time and budget.

Improved project coordination and reduced RFIs

When every discipline works from the same live model, questions drop. Fewer Requests for Information means fewer pauses in construction while someone hunts for an answer.

Real-time collaboration and version control

With a Common Data Environment, everyone sees the latest version — no one’s stuck with last week’s file. Every change is tracked, so nothing slips through unnoticed.

Quantification and cost estimation automation

Because model elements carry their own data, quantities, and costs update instantly when something changes. No more manual recalculations that eat into deadlines.

Time-saving through accurate scheduling

4D BIM links elements to construction timelines, making it clear what’s built when. That keeps crews, deliveries, and equipment in sync.

Integration with IoT and sensors for smart buildings

Once a project is complete, the BIM model can connect to live sensors, feeding back data on energy use, occupancy, or system performance for smarter operations.

Over To You

In the AEC industry, BIM is a game-changer!

The project delivery does not remain a fragmented workflow. Instead, it acts as a single, connected model. Apart from being a BIM 3D modeling tool, it becomes a system that keeps every discipline aligned from concept to handover.

When BIM is applied the right way, the results speak for themselves: fewer design errors, stronger coordination, earlier risk detection, and a clear path to meeting safety, cost, and sustainability targets.

At Next Synergy Solutions, we help AEC teams unlock these results through our BIM modeling services. Whether it’s creating accurate 3D models or supporting multi-disciplinary coordination, our work turns BIM from a requirement into a genuine competitive advantage.